2025 January Eptura Asset Product Release

January's release includes:

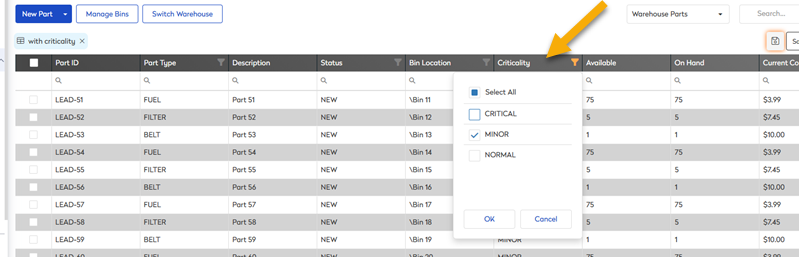

- Inventory module to include the Part Criticality column

- Cycle Count Schedule Automation Enhancement

- General Maintenance

January 30, 2025 Release

Inventory Module Enhancement

The Inventory grid now includes the Part Criticality column.

Learn more about the grid in Customize the Inventory View.

January 9, 2025 Release

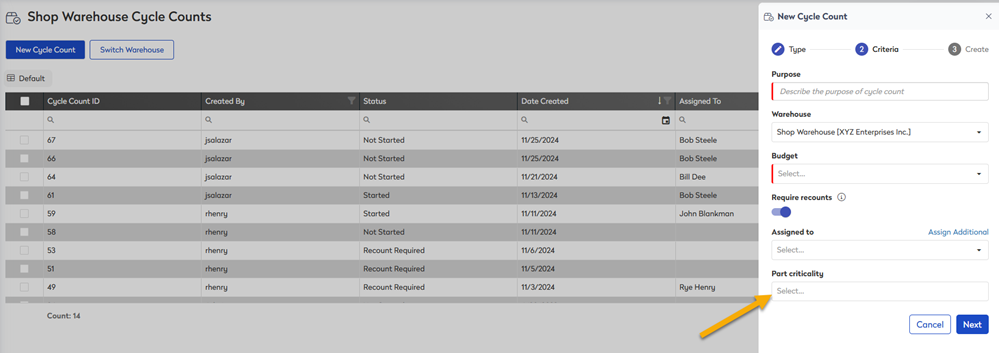

Cycle Count Schedule Automation Enhancement

Early Access

Many organizations face significant challenges in maintaining accurate and up-to-date inventory records for parts and materials. The manual process of creating and managing cycle counts is not only labor-intensive but also prone to errors and delays. This can lead to stock discrepancies, where items are either overstocked or run out of stock, causing operational inefficiencies and increased costs. Additionally, without a systematic approach, high-priority and high-turnover items may not be counted frequently enough, leading to stockouts that can disrupt operations. These inefficiencies and inaccuracies can also result in higher operational costs, including unnecessary storage and handling expenses, further straining the organization's budget and resources.

Cycle Count Schedule Automation is a systematic process that automates inventory audits by generating cycle counts at predefined intervals (monthly, weekly, yearly, or custom schedules). This ensures that inventory records are accurate and up-to-date without the need for manual intervention.

This enhancement lets you:

- Set up a scheduled cycle count that starts on a specific date and continues to generate on the set frequency.

- Define the importance of inventory parts, such as High, Medium, and Low, and include these in the schedule cycle count.

- For large volumes of parts, specify a sample size to ensure continuous counting with each cycle.

- Automate inventory counting based on customizable criteria such as bin location and part criticality.

- The system automatically generates a cycle count task at predefined intervals, reducing manual intervention.

Learn more in the Set up a Cycle Count Schedule.

The Part Criticality allows you to define the importance of a part by setting values like high, low, etc, to indicate its priority for counting. This can be set in the Part in the Inventory module.

Learn more in View the Part Details.

Your Administrator can define the values and by default, the Part Criticality settings are High, Medium, and Low, and you can add, edit, and delete these in the Inventory Settings.

Additionally, this can be used; when you create a new cycle count; you will be able to set the Part Criticality so that it only includes parts with the specified Part Criticality.

Learn more in Set up General Settings for Inventory.

General Maintenance

- Work Orders, Vendor, and Customer - The message “You do not have permission for that action” was incorrectly displayed for users with permission, so we fixed this.

- Work Orders - The work orders list wasn’t loading correctly; this has been fixed.

- Purchase Order - Allocated is not showing the related record on the Part Details when the part is on a return Purchase Order; this has been fixed.