Create a Maintenance Plan for a HVAC

Learn how to create a maintenance plan with this HVAC example, and this will include how to add a Part Kit.

Create a Maintenance Plan

- From the menu, click Settings.

- Under the Libraries heading, click Maintenance Plans.

- Select the category this plan will be filed under.

- Click the Create New Plan.

- Enter the name of the plan and press the Enter key.

- Click the Create New PM button.

New PM

- In the PM Name field, enter a name.

- In the Purpose field, enter a short description of its purpose.

- From the Work Type drop-down select either Preventive, Corrective, or Predictive. Note that PM's are typically preventive work.

Maturity Rules

- From the Set Work Order, select either No Due Date, Work Order Creation, or Schedule Due.

- For this example, we will set work orders to be due one day after they are created. Here we will tell the system that we want the PM schedule to reset after the work order is created.

- Click the Save button to create the PM.

More Options

You will see more options, such as Tasks, Part Kits, Priority, Schedule Rules.

Tasks

- Click the Add Task button and the Add Service Tasks dialog displays. This contains the service tasks or inspections you have previously created.

- From the Add Service Tasks dialog, you can filter tasks by category, search by name, or even create a new task.

- Select the task you want and then click the Add to PM button. This service task will display in the work orders created from this PM.

Part Kits

Early Access

Learn more about Part Kits availability in 2025 August Eptura Asset Product Release

Field technicians and maintenance teams often face challenges such as delays in finding and assembling parts, inefficient inventory management, and frequent errors in part usage. Technicians often encounter situations where they arrive at a job site only to discover they’re missing critical tools, parts, or materials required to complete the task. These issues can lead to delays in job completion, increased downtime, higher operational costs, and reduced customer satisfaction.

Park Kitting is designed to automatically assign asset-specific kits for work orders or preventive maintenance, including cost and stock details. This integration aims to reduce delays, optimize technician time, and improve inventory and procurement planning.

This will allow you to add individual parts to a Preventative Maintenance (PM) schedule. When the PM generates a Work Order (WO), the required parts are automatically included in the WO, ensuring that all necessary parts are accounted for.

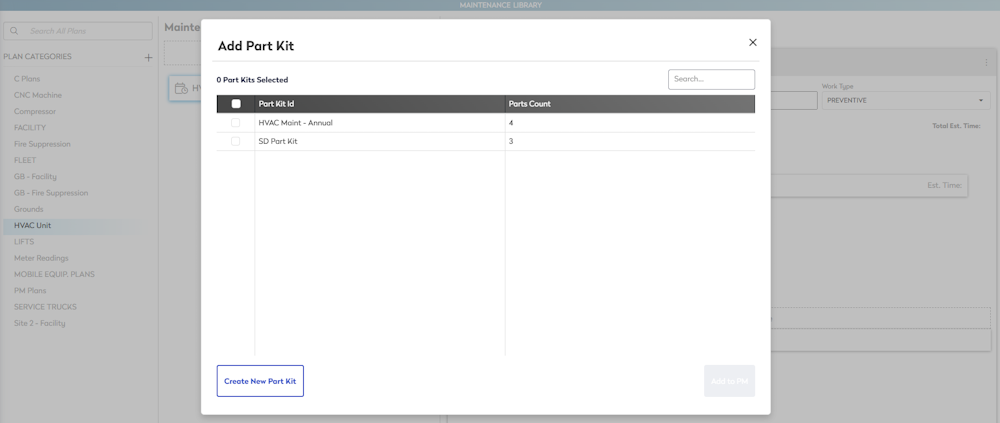

- Click the Add Part Kit button and Add Part Kit dialog displays.

- Click the Create New Part Kit button and the Create a New Part Kit dialog displays.

- In the Part Kit name field, enter the name.

- Click the Add Part button.

- Search for the part name and then select it.

- Click into the Quantity field, and enter the number.

- Repeat the steps 5 to 6 to add more parts.

- When you are finished, click the Save button OR you can click the Save & Select button

As you are creating the part kit, you can add or remove parts, change the quantities, and sort the Part Id column.

- Click the Back button to return to the Part Kit list.

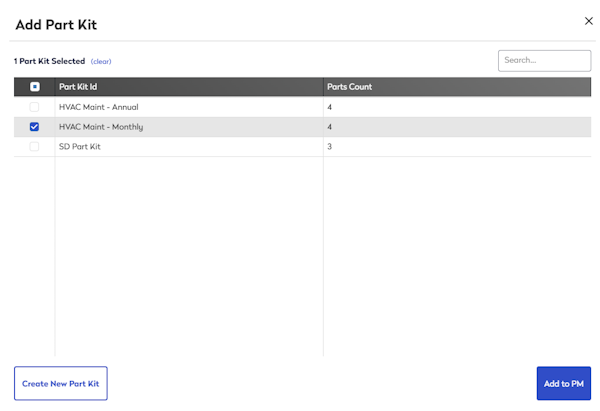

- Check the Part Kit's check box that you want to add to the PM. You can select multiple Part Kits.

- Click the Add to PM button and the Part Kit is added to the PM.

The part kit's parts will display in the work orders created from this PM.

If you need to rename or modify a Part Kit, then the kits will be found in the Part Kit Library.

Priority

Select the priority level you want, and this lets you mark some PMs as more or less important than others.

Schedule Rules

Schedule rules is where you will tell the system how often this PM will occur.

- Click the Create New Rule button.

- Complete the following:

Schedule by - Schedules can be based on:

- Asset logs - Either Log Progression or Log Reading.

- Time - Either Day or Month, Days, Months, or Years.

Repeats every - This PM will be set to be completed every Monday.

Add Season - You can add a season if you only want the PM to be active for a certain part of the year.

- Repeat the above process to add multiple PMs to the maintenance plan.

The PM can have more than one schedule rule applied. It will trigger on whichever rule happens first.

Maturity Rules

These rules were set up when you first created the PM above.

Linked Schedules

Linking PMs results in fewer work orders by allowing the system to synchronize PM schedules and mitigate redundant downtime for assets. Fewer work orders means consolidated tasks, which means less paperwork.

- Click the Create New Link.

- From the drop-down, select a PM to Link.

- From the Link Type drown-drop, select either Include or Override.

Learn more about linking in either Linking PMs - Sprinkler System Example or Linking PMs - Truck Example.

Now your maintenance plan is complete and ready to be assigned to the HVAC asset!